27BEIPP6463H1Z2

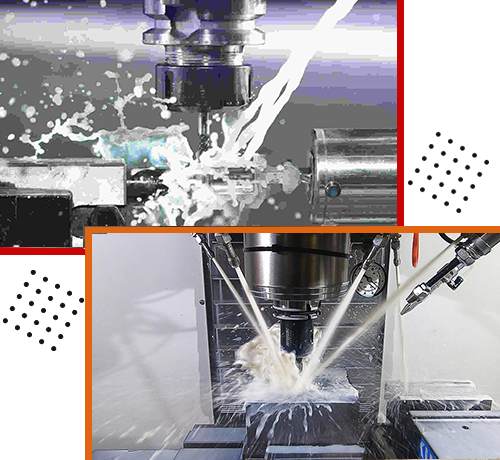

High Pressure Coolant Supply Unit

The “High pressure coolant supply unit”

helps to dissipate the extensive heat of the cutting process

more effectively than the traditional flood cooling methods.

With this approach, coolant penetrates the cutting zone deeper

and more focused, allowing for better coolant flow and higher

temperature reduction through convective heat transfer

Benefits of high pressure coolant

The importance of cooling in machining operations is

incontestable. Cooling fluids prolong the tool life and aid

in the control of the workpiece geometrical properties.

Both these features play a significant role on the final

part quality, surface integrity, and life cycle. For this reason, most machine tools possess rather simple coolant

supply systems. Although these systems offer adequate

cooling and lubrication conditions in many machining

practices, the effect of cooling and lubrication can be

further improved, especially in the case of hard-tomachine materials like titanium alloys. Such improvements include the promising method of high-pressure

cooling among others. The ongoing studies indicate that

the application of a coolant with high pressure in thencutting zone can be beneficial in many ways.

Best suitable for imported precision machine tools

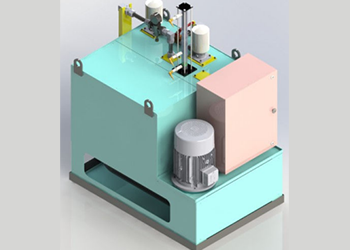

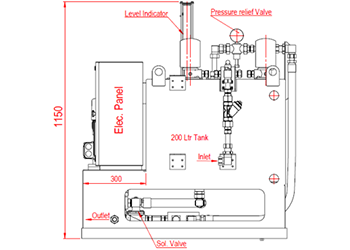

Technical Specifications :

| Sl. No | Description | Unit | Remark |

| 1 | Tank capacity | Ltrs/ US.G | 190 / 50 |

| 2 | Max working pressure | Bar/ PSI | 36 / 522 |

| 3 | Allowable Pr. Setting | Bar/ PSI | 15 to 35 / 217.5 to 507.5 |

| 4 | Max Flow | LPM / GPS | 48 / 12.5 |

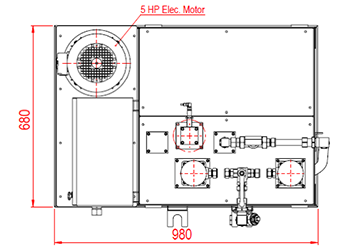

| 5 | Motor Power | kW / HP | 3.7 / 5 |

| 6 | Coolant Type | --- | Water emulsion |

| 7 | Filtration Level | µm | 25 |

| 8 | Mounting type | µm | Stand-alone with castor wheels |

| 9 | Elec. Supply | Volts/ Hz | 3 Ph. 415V. 50 Hz |

| 10 | No. of filters | 2 | 1 working / 1 stand-by |

| 11 | Coolant level sensor | -- | Tubular type |

| 12 | Pressure protection | Thru Pr relief valve | |

| 13 | Pr. Indication | -- | Visual indicator (Gauge) |

| 14 | Dry run protection | -- | Provided thru proximity switch |

| 15 | Dimensions | mm | 650 x 650 x 750 |

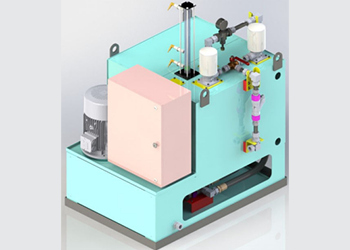

Optional Features :

- Flow up to 110 LPM (29 USgpm) with pressure up to 35 bar (507.5 PSI).

- Coolant chilling unit (Capacity according to usage)

- Filtration up to 5 µm with high flow capacity

- Multiport connections with solenoid valves for additional fixture flushing, base flushing, etc,.

- Additional by pass valve for pressure protection.

- Further customization according to the functional needs.

Performance :

- Dip Hole Drilling

- Pocket Milling

- Heavy Cutting

Efficiency :

- Hogh Speed Cutting

- High Production Rate

- Increase Tool Life

Quality :

- Better Surface Finish

- Geometrical Accuracy

- Compact floor space requirement

- Effective & reliable working unit

- Low cost solution

- Enegy saving

- Safety interlocks to avoid overflow & pressure protection

- Provision for spare ports for additional 2 way valve

Facebook

Facebook  Whatsapp

Whatsapp  Linkedin

Linkedin  Instagram

Instagram